Yesterday was the day that i went to the printers..

Private parking for visitors

Let's enter the building, armed with the sheets that gyruss picked up for me, and Andre transported back to his place, where i could pick them up, since thats on route from and to my job many times in the week.

Thank you guys !

First thing that i noticed was this cool ceiling that they have printed. cool decoration for a gameroom too !

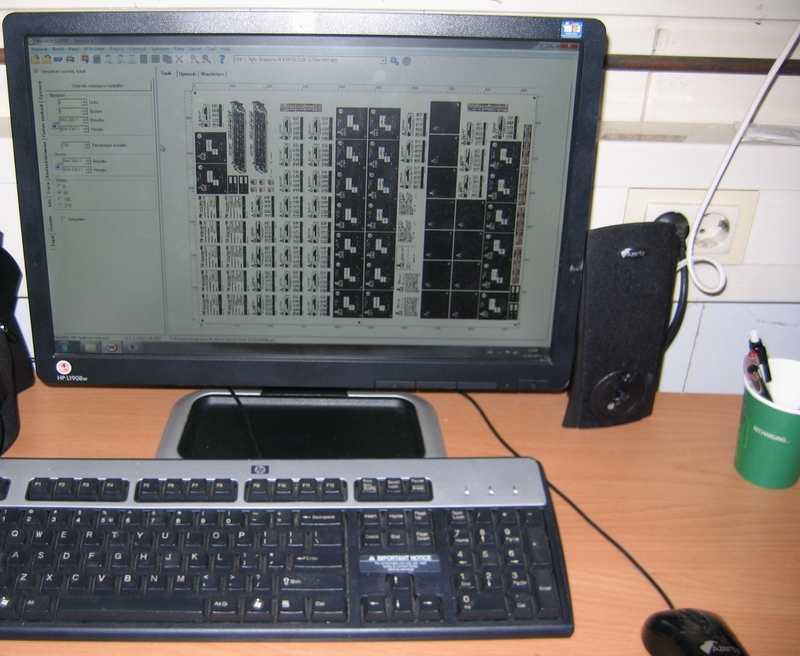

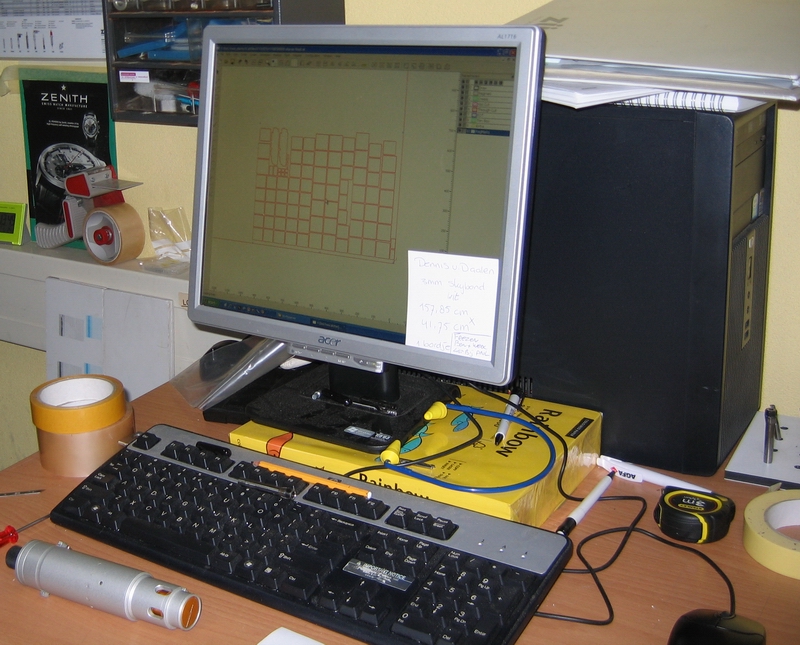

After some chatting with the owner and a tour through the company, i handed the files to his co-worker who started edditing and verify the files.

In the process he separated the magenta lines that i specified as "cutting lines".

Lets take it to the press

Now seriously,

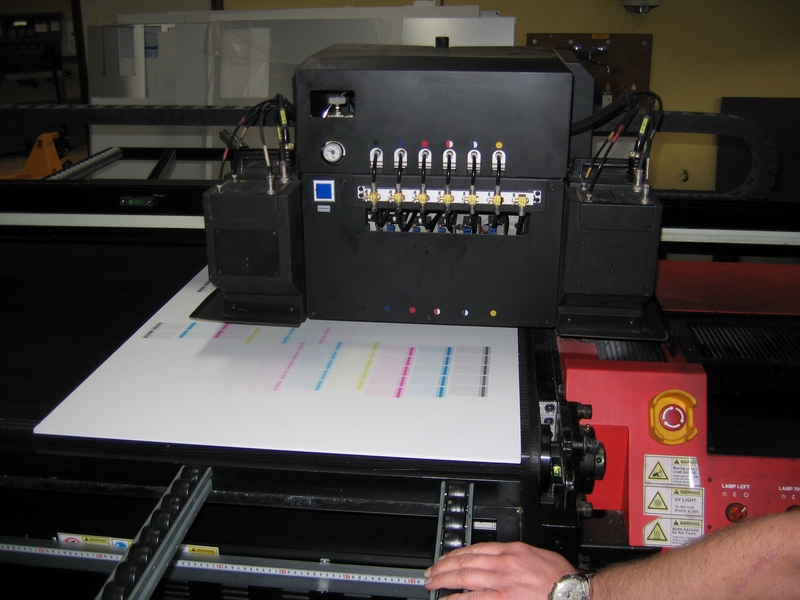

The guy finishes the previous job on the printer, and recalibrated the printer for my job.

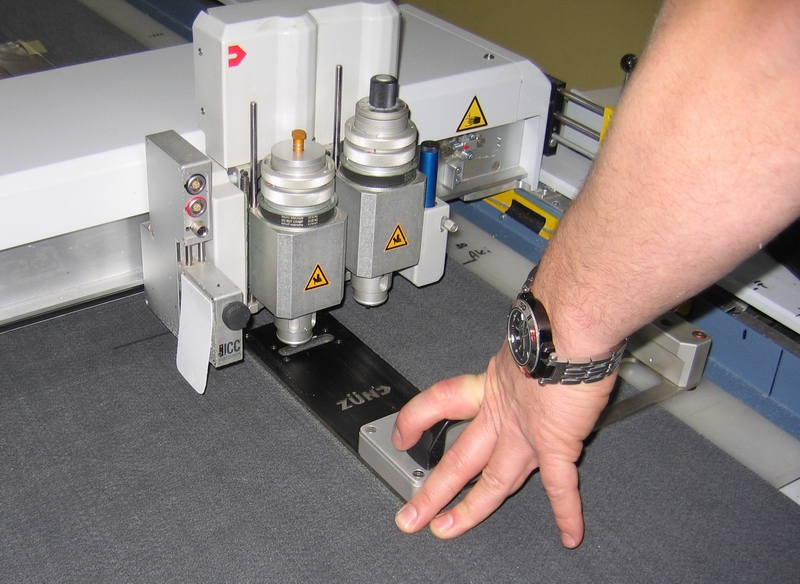

Calibration in progress..

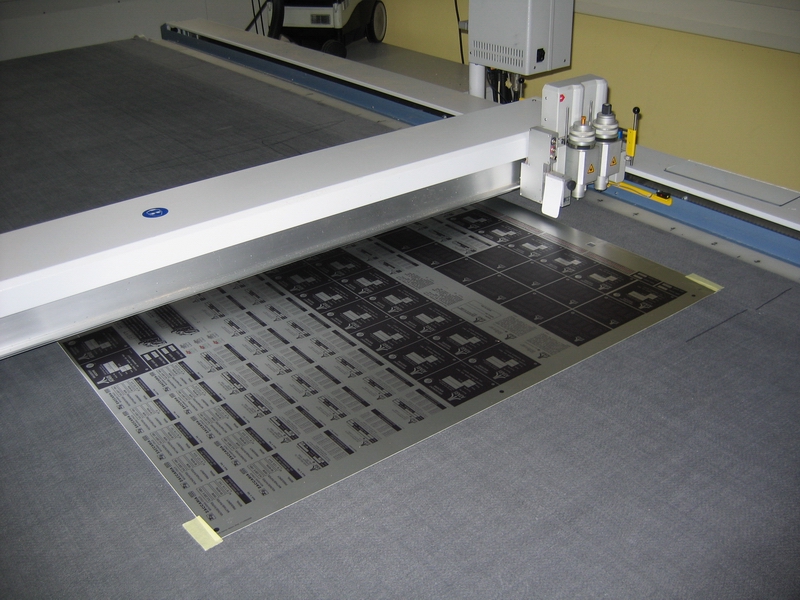

First file loaded into the printer..

Starting up the printer, it checks its temperatures and that kind of things..

Placing the sheet to the conveyor belt, although the belt sucks the sheet to it by vaccuum, we still needed to tape it down since the corners had some wrinkeling due to transport

Luckily it was outside of the printing area..

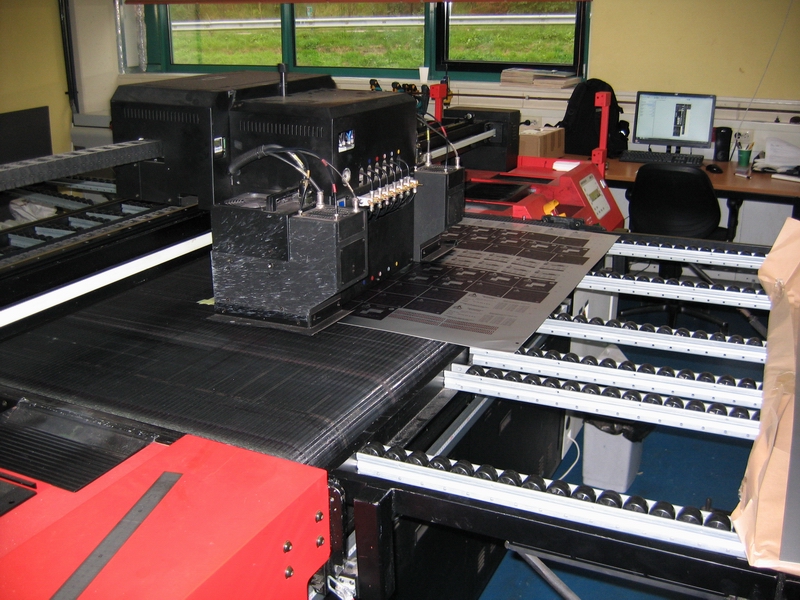

Loading the next sheet, again same process, lining out and tape it in place..

Printing in progress..

Here the owner is finishing the cutting job he was working on, after that its the alusheet's turn..

now the tricky part, since this is the first time they needed to cut this kind of material, it will be some trial and error...

the material is not supplied by them, and before we made the appointment back in the beginning of the year they already told me it could go wrong.

but anyway, they really wanted to try it and see if they can do it.

so they did all they can to make it a succes, a big plus for the printguys if you ask me.

they do cut aluminium and other materials, but then they mill it, but this is too thin to mill...

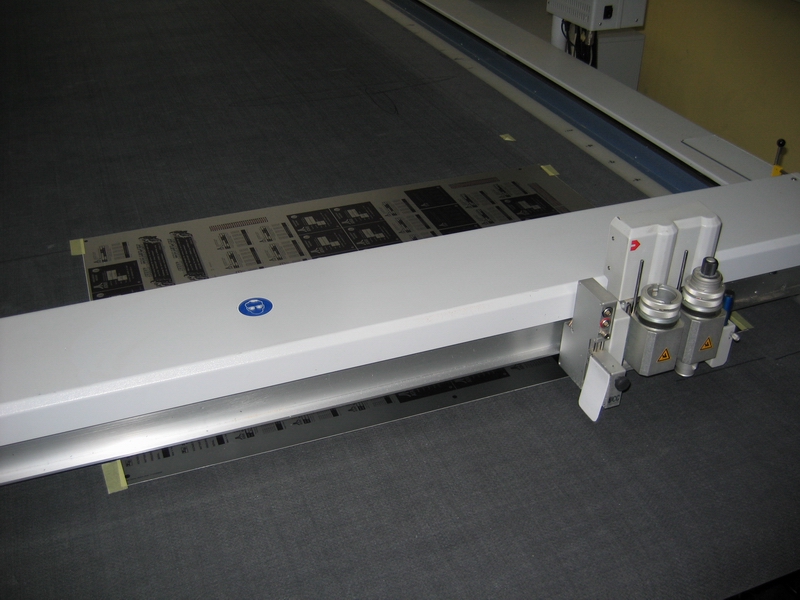

the sheet is in place, and again taped to the conveyor belt..

First test, cutting totally through the sheet, cutterhead is removed to install a brand new knive..

recalibrating the knive, and its time to do some tests...

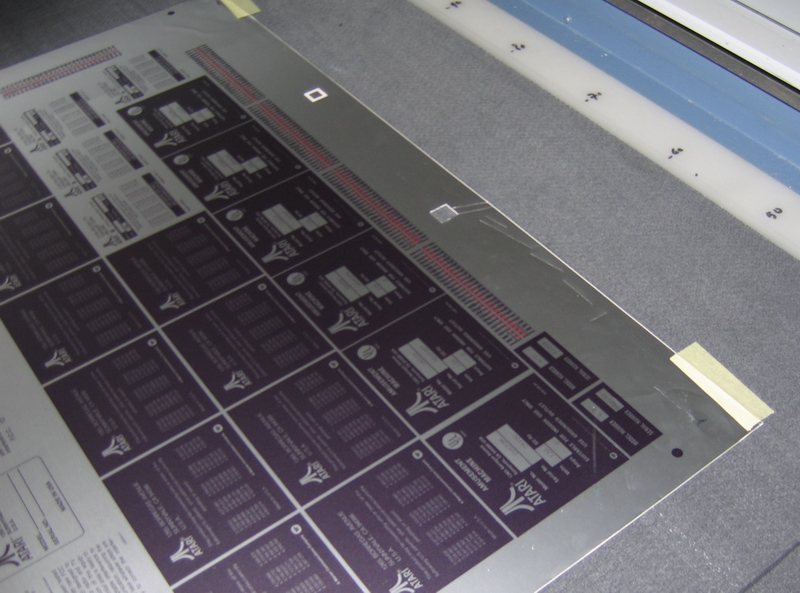

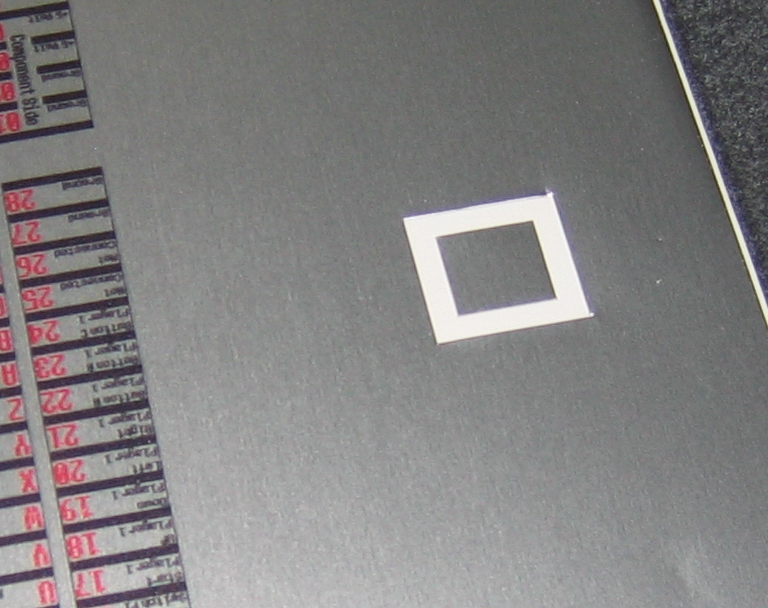

Don't know if you can see it good here, but we tried a cut first on the side.

(the little square in the right side)

that test gave not the desired result, while cutting, the material gave jaggered edges so cutting through was not an option..

Another test, "slitting" (where another special kind of knive cuts only the top layer), the knive is much more "flat" so it slides better through the material..

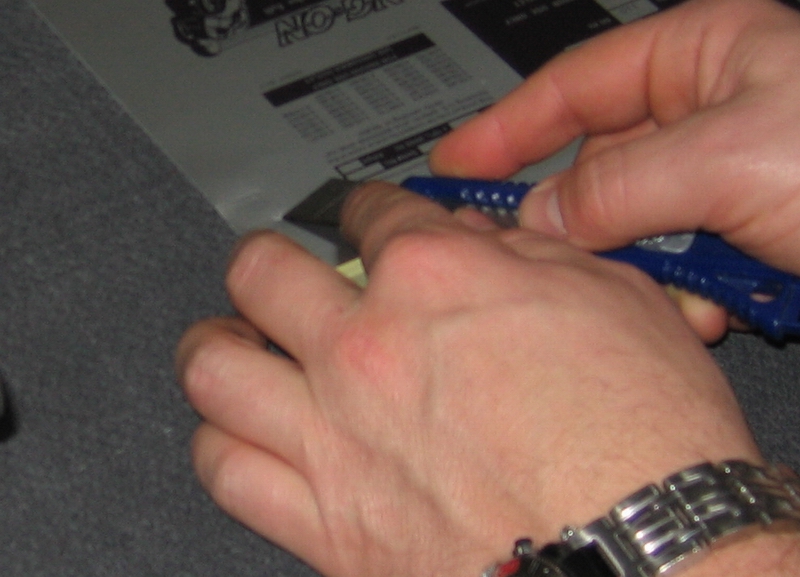

after the testcut, carefully removing the testcut...

Hmm, looks very prommising !

straight edges, and a nice sharp cut..

Contours loaded into the cutting device, ready to start..

Now disatergirl came around the corner...

and after some investigation of the knive, the guy came to the conclusion that after the first testcut, the knive was already dull!

because it is aluminium, the slitting was in fact metal to metal contact, which made the knive dull instantly...

There was ofcourse a possibility to change the knive after every sticker, but at 30€ a knive that would make the stickers very very expensive !

so we decided to cut them manualy...

I have the sheets at home now, and i need to cut them with a utility knive...

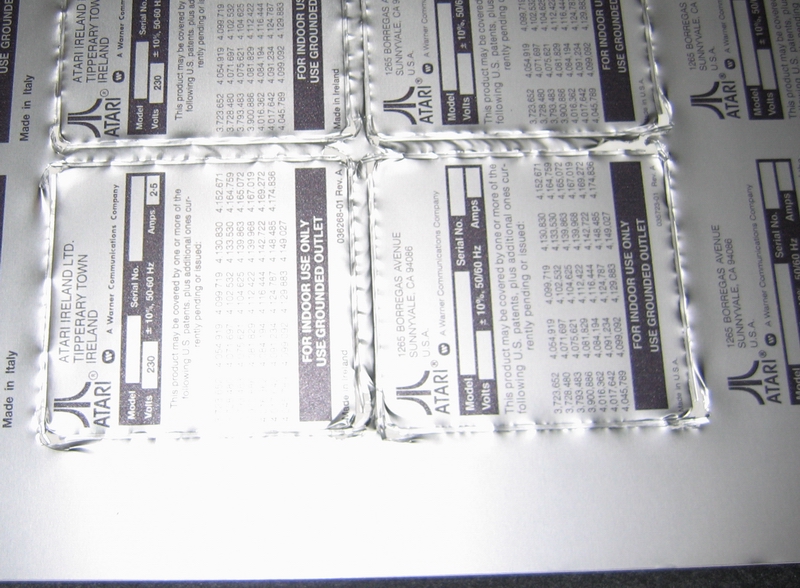

But there was one good thing, the cutting machine will be recognised in the future as it is labeled as an Atari !

So it was a 50% succes, the printing is done with UV ink which is dried instantly by the two UV lamps in the print head.

I will cut the stickers "roughly" so you guys can make the corners with scissors if desired..

for the final price i need to wait for the invoice, so i can devide it..

It was a bit of a dissapointment for the cutting part, also for the printguys..

believe me they tried everything in they're power to fix it, but it was not doable.

They did give me another tip, which is lasercutting, but they dont have that equipment, and probably will raise the price again..

The only problem now is the etikets with rounded corners, the straight cuts i can do with the utility knive, so it was not all for nothing..

Lets see what will happen...

I need to find me some time to start cutting

Youtube video's of the printing and cutting :

PrintingCutting